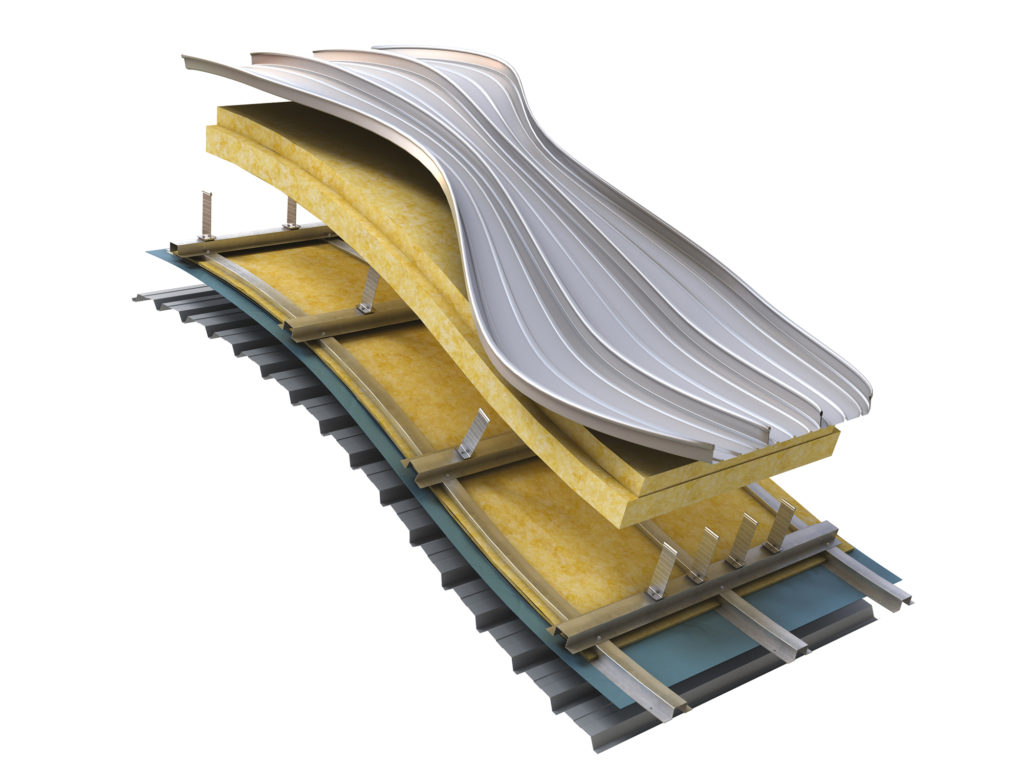

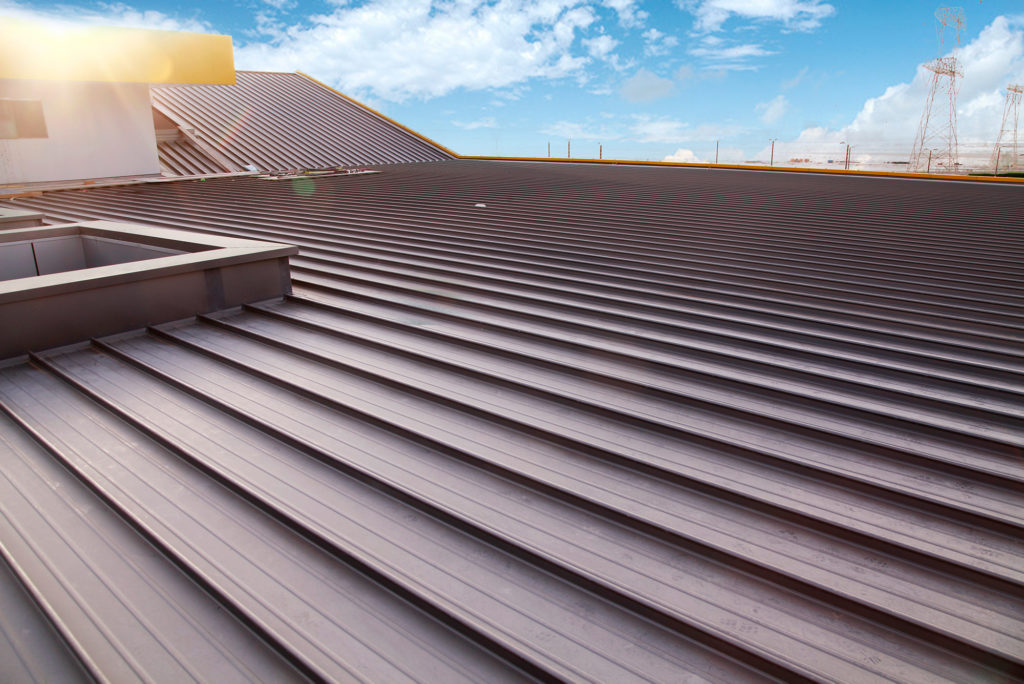

Predominantly manufactured in aluminium, KingZip is available in stainless / coated steel, zinc or copper and can be supplied smooth, embossed, crimp curved, concave or convex smooth curved, tapered, wave formed or tapered and smoothly curved.

KingZip SF

KingZip SF is a mechanically zipped roofing system. The standing seam top sheets offer the flexibility to be either site or factory roll formed in straight, tapered or curved sheets to achieve complex building geometry

For more information

3D KingZip SF Product Specification

| No. | Product | Specification/Capability | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Max/Min sheet cross section | Limits for rollformer: Wmax = 1000 mm (with container side open) 800 mm (with container side closed, need to use edge trimmers) Wmin=130 mm Limits for curving machine: Wmax=1000 mm Wmin= 190 mm |

||||||||||||||||

| 2 | Min sheet tapering criteria | Limited by trimming action of 700mm max (350mm from each edge) From 100 to 800 mm or From 300 to 1000 mm |

||||||||||||||||

| 3 | Max variable path angle | +/- 10 ° on short lengths +/- 8 ° as average |

||||||||||||||||

| 4 | Min/Max radii on variable width | Rmin = 10 to 20 mtrs, gauge and shape dependent | ||||||||||||||||

| 5 | Rib path for varible width to follow seam path | Side mini ribs following standing seam path at a distance from 70 to 250 mm; Center mini rib always following the centre of the profile, also the freeform profiles. |

||||||||||||||||

| 6 | Sheet length tolerance | Tolerance +/-0,5% on length | ||||||||||||||||

| 7 | Max/Min sheet concave radii | Material: Aluminum, 2 mini ribs

It is required to process the profile performing through progressive passes through the curving machine to get final curved shape, particularly when target radius is tight. Subject to complexity of shape and sheet; 3D curve radius required |

||||||||||||||||

| 8 | Max/Min sheet convex radii | Material: Aluminum

It is required to process the profile performing through progressive passes through the curving machine to get final curved shape, particularly when target radius is tight. Subject to complexity of shape and sheet; 3D curve radius required |

||||||||||||||||

| 9 | Min sheet length | 2750 mm | ||||||||||||||||

| 10 | Max taper width | Wmax = 1000 mm (with container side open) 800 mm (with container side closed, need to use edge trimmers) |

||||||||||||||||

| 11 | Min taper width | Wmin = 130 mm for uncurved panels Wmin = 190 mm for curved panels |

||||||||||||||||

| 12 | Aluminium material gauges | Aluminium 0.7 to 1.2mm |

Acoustic performance is a key requirement on many projects, especially public use buildings. Kingzip Linea has the flexibility to meet the acoustic performance specifications for any building.

Acoustic Board – Gypsum Board 720kg/m3 density

Cement Board – 1,250 kg/m3 density or specific high density rubber mat

Sound Reduction – Rw values from 36dB to 50dB

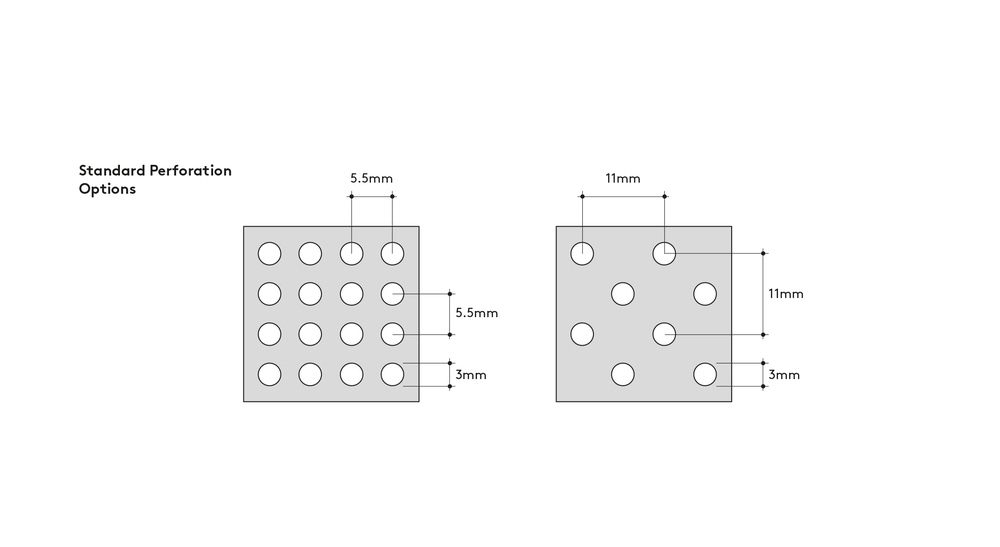

Sound absorbtion – NRC values from 0.5 to 0.85 for our standard perforation patterns. Project specific NRC values on request.

Fire Performance

Kingzip Linea achieves a class 0 rating as defined in various national building regulations. These systems are classed as non – combustible.

| Test | Result |

|---|---|

| BS 476-3:2004 Classification and method of test for external fire exposure to roofs | FAA/SAA |

| BS 476-6:2009 Method of test for fire propagation for products | 1< 12 i < 6 |

| BS 476-7:1997 Method of test to determine the classification of the surface spread of flame of products | Class 1 rating for aluminium/steel inner/outer metal facings |

| FM 4471 Panel Roofs | Class 1A |

Our Kingzip roof systems are manufactured and supplied under:

ISO14001:2004

BS EN ISO 9001

Compliant with ASTM E1637

Systems with UL 580-90 certification are available